Atualmente, os utilizadores de zircónia dentária têm muito por onde escolher. Inúmeros fabricantes oferecem materiais de zircónia que diferem nas suas propriedades mecânicas e ópticas e na gama de indicações. O que não é evidente à primeira vista é que os produtos disponíveis também diferem no que respeita à qualidade da oferta dos materiais CAD/CAM em bruto. A qualidade dos materiais em bruto depende muito da qualidade das matérias-primas e é afetada por diferentes aspetos durante o processamento, prensagem e pré-sinterização. Isto tem um impacto enorme na qualidade da superfície, na estabilidade das margens, no ajuste e nos requisitos de processamento das restaurações fresadas.

Produção de matérias-primas

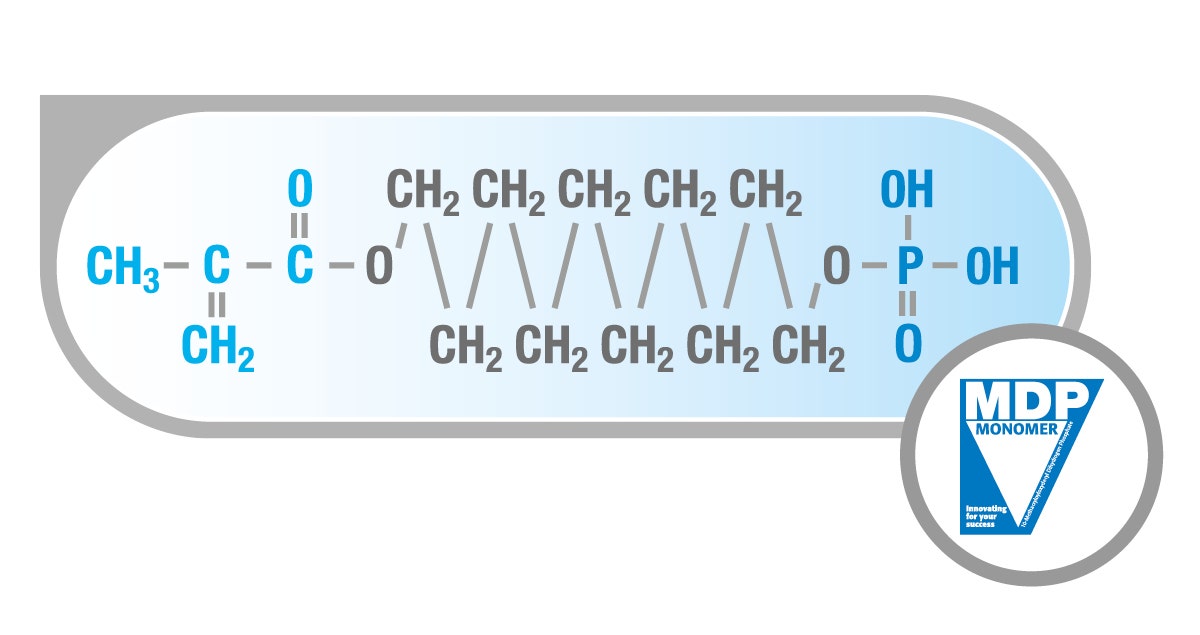

A zircónia dentária pré-colorida é normalmente constituída por óxidos metálicos, incluindo óxido de zircónio, óxido de ítrio e óxido de alumínio, e também aditivos como aglutinantes e pigmentos ou iões coloridos. A maioria dos fabricantes de zircónia dentária obtém o pó pré-fabricado a partir de um parceiro externo da indústria, sendo a opção mais popular a Tosoh Corporation. Ao contrário, a Kuraray Noritake Dental baseia‑se num processo interno do princípio ao fim. Isto inclui a produção e adição dos componentes que formam a inovadora tecnologia multicapa da empresa para uma obter uma estrutura policromática em bruto e - no caso da "KATANA™ Zirconia" YML - obter translucidez adicional e gradação da resistência à flexão.

Na Kuraray Noritake Dental, o pó é produzido internamente.

Uma vez que mais etapas de produção de pó são realizadas internamente, a empresa tem controlo total sobre a qualidade das matérias-primas, sobre o tamanho de grão e a pureza da formulação. Isto também permite um alinhamento exato das propriedades mecânicas e ópticas do produto para conseguir uma transição suave de uma capa para a seguinte. O resultado é uma estrutura de cores sem descontinuidades e uma excelente correspondência das cores dos discos policromáticos com as cores do guia de cores VITA clássico A1-D4.

Nos materiais que combinam diferentes concentrações de ítria numa única peça em bruto, podem ser tomadas medidas internas adicionais de alinhamento. No caso do "KATANA™ Zirconia" YML, foi desenvolvida uma matéria-prima completamente nova para proporcionar uma taxa de contração uniforme e coeficientes harmonizados de expansão térmica em toda a peça em bruto e, assim, levar à perfeição a gradação da resistência à flexão.

As propriedades das restaurações de zircónia que são afetadas pela qualidade e composição do pó incluem a translucidez e o aspeto da cor, a resistência à flexão, o comportamento de envelhecimento e o desempenho da sinterização.

Prensagem do material em bruto

Os discos e blocos de zircónia utilizados para o processamento CAD/CAM são normalmente produzidos por prensagem uniaxial e isostática. No processo de compactação uniaxial, a pressão é aplicada ao pó a partir de uma direção (uniaxial) ou de duas direções (biaxial), enquanto o processo de compactação isostática envolve uma pressão praticamente igual aplicada de todos os lados. Por conseguinte, a prensagem isostática resulta normalmente numa distribuição mais uniforme da densidade em toda a peça em bruto e numa maior homogeneidade do material. Estes fatores são pré-requisitos para um comportamento previsível de processamento e sinterização e afetam o ajuste da restauração final. Para obter propriedades mecânicas e ópticas ótimas do material de zircónia, é essencial evitar grandes porosidades, bolsas de ar e impurezas causadas por partículas transportadas pelo ar que ficam presas durante a prensagem.

Na Kuraray Noritake Dental, um processo de prensagem único e extremamente meticuloso consegue uma distribuição uniforme da pressão e um baixo risco de contaminação por partículas transportadas pelo ar. Este procedimento específico reduz as forças de gravitação e contribui para uma densidade tão elevada quanto possível do material de zircónia. Todos os processos de preparação de alto nível, desde a produção da matéria-prima até à prensagem, são responsáveis pela elevada estabilidade das margens e pela qualidade da superfície das restaurações fresadas a partir de "KATANA™ Zirconia".

Pré-sinterização

O procedimento de pré-sinterização é necessário na medida em que confere aos blocos prensados a estabilidade necessária para poderem ser maquinados com ferramentas de fresagem. O perfil de temperatura selecionado e a duração do ciclo de pré-sinterização determinam a resistência do material e as propriedades de processamento e têm impacto no processo de sinterização final.

O procedimento único de pré-sinterização efetuado nas unidades de produção da Kuraray Noritake Dental produz peças em bruto que são estáveis no seu estado pré-sinterizado. Embora mais estável, o "KATANA™ Zirconia" pré-sinterizado é maquinável com ferramentas de fresagem comuns com revestimento de diamante, sem qualquer risco acrescido de quebra ou maior desgaste da ferramenta.

Sinterização rápida no laboratório

O procedimento único tem um impacto positivo na suavidade da superfície após a fresagem e pode reduzir significativamente os tempos de sinterização. No laboratório de prótese dentária, os tempos de sinterização podem ser reduzidos para 54 minutos* para restaurações unitárias e pontes de até três elementos - uma opção interessante para casos urgentes e repetições.

*O material é retirado do forno a 800 °C.

O YML "KATANA™ Zirconia" foi sinterizado rapidamente (programa de sinterização de 90 minutos), enquanto os discos dos concorrentes foram sinterizados utilizando programas de sinterização típicos de um dia para o outro, adequados para o material específico. Mesmo com uma sinterização de 90 minutos, o KATANA™ Zirconia YML apresenta propriedades ópticas superiores em comparação com os principais concorrentes.

São oferecidos programas de sinterização uniformes para toda a série multicapas "KATANA™ Zirconia"

Visão geral dos protocolos de sinterização recomendados.

Sinterização rápida no consultório

Ao utilizar o bloco "KATANA™ Zirconia" com o sistema CEREC da Dentsply Sirona, é possível sinterizar coroas unitárias ou pontes de até três elementos em 18-30 minutos sem comprometer as propriedades mecânicas ou ópticas.

Os blocos "KATANA™ Zirconia" apresentam propriedades ópticas superiores após 18 minutos de sinterização em comparação com amostras de matérias-primas dos principais concorrentes após programas de sinterização de 30 e 60 minutos concebidos pela Kuraray Noritake Dental, com base nas recomendações do fabricante.

Propriedades únicas da "KATANA™ Zirconia"

Em conjunto, estes esforços realizados pela Kuraray Noritake Dental para produzir zircónia dentária de alta qualidade fazem toda a diferença. A série "KATANA™ Zirconia" - "KATANA™ Zirconia" Yttria Multi Layered (YML), Ultra Translucent Multi Layered (UTML), Super Translucent Multi Layered (STML), High Translucent Multi Layered Plus (HTML Plus) e KATANA™ Zirconia High Translucent Mono Layered (HT) - tem uma estrutura homogénea de alta densidade com baixa porosidade e um elevado nível de pureza. Além disso, o "KATANA™ Zirconia" YML oferece uma estrutura contínua, sem linhas de transição, apesar da gradação da resistência à flexão. Todas estas propriedades otimizam o desempenho das peças em bruto durante a maquinação.

Imagens MEV de "KATANA™ Zirconia" não polida e de um material da concorrência com uma ampliação de 33×. As quatro imagens de cada material mostram a estrutura da superfície em diferentes áreas de uma coroa de um molar. Em todas as áreas, a superfície da restauração feita com o material da concorrência é mais áspera e apresenta mais porosidade do que a superfície da coroa de "KATANA™ Zirconia" diretamente após a fresagem, de acordo com os resultados da investigação do Dr. Josef Kunkela. Um dos fatores que contribui para este resultado da "KATANA™ Zirconia" é o disco em bruto mais densamente prensado e com tamanhos de grão mais pequenos. (Cortesia da Academia de Investigação Kunkela pelo Dr. Josef Kunkela).

Rugosidade da superfície

Um comportamento otimizado durante o processamento produz margens de restauração regulares, superfícies lisas e um ajuste preciso das restaurações. Este último aspeto deve-se ao facto de o comportamento de fresagem e a contração volumétrica durante a sinterização final serem altamente previsíveis, de modo que um utilizador que projete um espaço para o cimento de 20 μm obterá exatamente o que deseja. Graças ao grande controlo das propriedades ópticas e à excelente correspondência com as cores VITA clássicas A1-D4, o "KATANA™ Zirconia" é considerado uma das opções de zircónia dentária mais estéticas disponíveis no mercado.

Excelente ajuste marginal

Imagens MEV que mostram o ajuste de restaurações realizadas com dois materiais diferentes (dissilicato de lítio e "KATANA™ Zirconia" Block STML) num pilar dentário. A restauração de "KATANA™ Zirconia" mostra uma margem mais regular e um ajuste mais preciso (com um espaço para o cimento de 19-21 μm) do que a coroa de dissilicato de lítio (espaço para o cimento 26-45 μm). (Cortesia da Academia de Investigação Kunkela pelo Dr. Josef Kunkela).

Margens extremamente regulares de uma coroa de "KATANA™ Zirconia" após a fresagem, o que também é um resultado da estrutura favorável do material.

Para garantir todas as propriedades desejadas do material, incluindo a estética e a resistência, uma coisa é essencial: a maquinação efetuada no laboratório de prótese dentária - fresagem e sinterização - tem de respeitar os protocolos recomendados. Isto significa que a máquina de fresagem e o forno devem ser limpos e calibrados regularmente, o que proporciona as condições para um processamento otimizado da zircónia desde o pó até à restauração dentária final, fiel à realidade.

Mathias Fernandez Y Lombardi

Gestor Científico da UE Cerâmica dentária e materiais CAD/CAM

Kuraray Europe GmbH