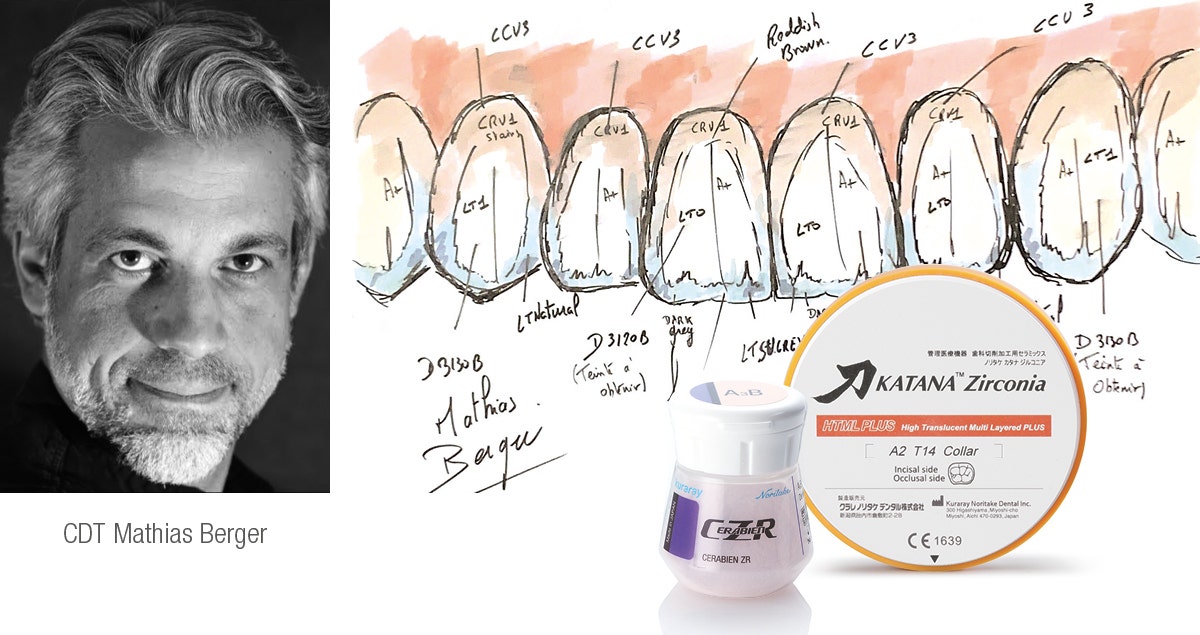

The KATANA™ Zirconia family of multi-layered CAD/CAM blanks has a new member: KATANA™ Zirconia YML (yttria multi-layered). Based on Kuraray Noritake Dental Inc. (KND) proprietary multi-layer technology, this new material offers multiple layers with different levels of chroma and translucency PLUS different concentrations of yttria in a single blank. We talked to two experts from Kuraray Noritake Dental’s Research & Development Department in Japan, Atsushi Matsumoto and Yuta Tajima, about the new product and its specific features.

Mr. Matsumoto, Mr. Tajima, KND already offers a broad range of zirconia materials covering virtually every indication. Why did you decide to start developing yet another dental zirconia?

The KATANA™ Zirconia series has indeed received high praise and great feedback from the market. Users particularly appreciate the remarkably high strength of HTML, the well-balanced aesthetic and strength properties of STML, and also the high translucency of UTML. Although there has been a large increase of zirconia materials in the dental market recently, we have received many requests from our customers for a more universal material that offers the excellent properties of all variants of KATANA™ Zirconia in one product. This product should allow them to fabricate all kinds of restorations from a single disc, from single crowns to full bridges, while maintaining high aesthetic and mechanical properties for both anterior and posterior restorations. As the developer of the KATANA™ Zirconia series, the invention of KATANA™ Zirconia YML is our response to these desires expressed by our customers.

What is the main difference between KATANA™ Zirconia YML and the other available products of the KATANA™ Zirconia Multi-Layered Series?

All layers of KATANA™ Zirconia UTML, STML and HTML are produced from the same basic powder composition and therefore offer the same strength throughout the whole blank. Depending on the case specific requirements, users need to select the most suitable type of material, either a high-strength zirconia or a highly translucent variant. KATANA™ Zirconia YML is an all-in-one zirconia suitable for all cases: It consists of a high-translucency enamel layer, an intermediate layer offering well-balanced strength, translucency and colour, and a high-strength body layer. The raw materials used for this product are developed and produced by KND exclusively for YML. This is another milestone in advanced product development KATANA™ Zirconia.

We have received many requests from our customers

for a more universal material.

In general, the currently available zirconia materials with an integrated strength gradient do not have a very positive image in the eyes of many dental technicians and specialists, due to the fact that in the incisal area, the materials seem to be insufficiently strengthened. This can lead to fractures when it comes to long-span restorations, especially if they are inadequately positioned within the blank. How carefully did KND focus on these problems and how did they try to solve them in order to stand out from the competition?

The current yttria-based multi-layer products on the market are facing complicated limitations in connector position in large cases, such as full-arch restorations, due to the lack of an ideal combination of aesthetics and strength. To overcome this challenge, KND developed well-balanced raw materials of high strength and high aesthetics, and by including these raw materials in the intermediate layer between the enamel and body layers. The result is that even for long-span restorations, it is very simple to position the connectors thanks to its excellent balance between high strength and high aesthetic properties. Due to these unique attributes incorporated in our new product, the risk of deformation and breakage is avoided.

Another problem is the often clearly visible line between the different layers containing different amounts of yttrium oxide, which can be seen at a more detailed inspection after sintering. How did you address this issue?

At KND, we achieved both, adequate translucency gradation and invisible transition lines, even for zirconia layers with different yttria content. This has been accomplished thanks to our multi-layer zirconia manufacturing technology refined over many years, which includes mixing the appropriate amount of each layer's boundary to intentionally avoid transition lines. In addition, the newly developed interlayer raw materials and a newly designed sintering schedule were the keys to success.

How is it possible to have a sintering protocol that works for different zirconia components within the KATANA™ Zirconia YML blank and allows for the shortest sintering times ever?

The amount of shrinkage during sintering is determined by different factors such as the number and quantity of additives (yttria, alumina etc.) it contains. If the shrinkage ratio of each layer is different, transition lines are likely to appear between the layers, which might produce tensions in the material structure. The newly developed raw material for KATANA™ Zirconia YML enables us to control and unify the shrinkage ratio for all layers, even for raw materials with different yttria contents.

The use of proprietary raw materials produced in-house with excellent properties suitable for high-speed sintering was the main precondition that allowed for the development KND’s high-speed sintering schedule (54 min for restorations up to 3-unit bridges), which is available for all products of the KATANA™ Zirconia multi-layered series. This option improves the efficiency of the dental technician’s work and simplifies the workflow.

|

|

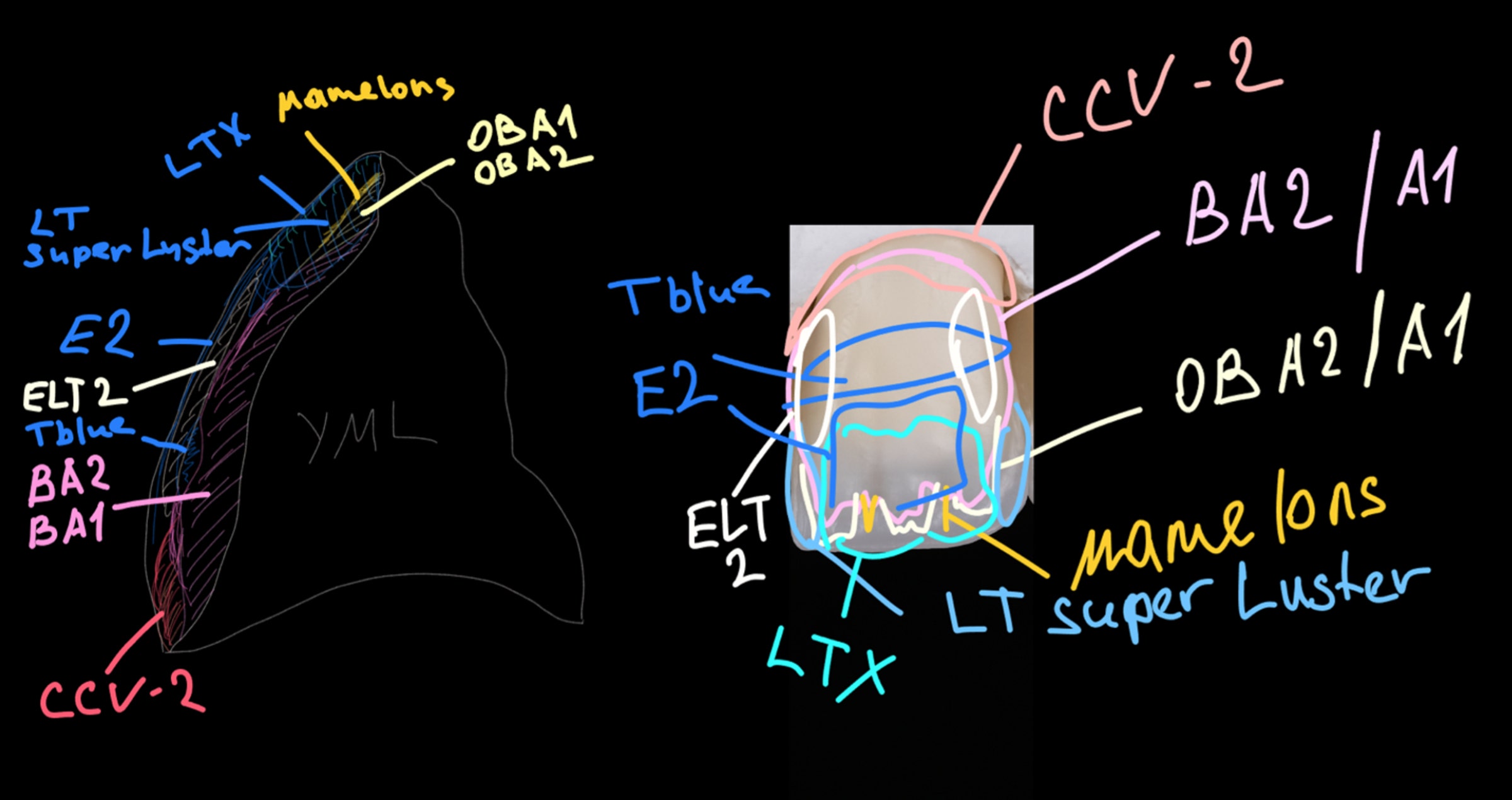

Enamel Layer

To provide high translucency that harmonizes with the anterior teeth.

Body Layer 1

To provide seamless color and translucency towards the Enamel Layer.

Body Layer 2, 3

To provide deep and vivid color while reducing whitening.

|

Are there any differences in milling and adjusting KATANA™ Zirconia YML compared to competitor products?

All KATANA™ Zirconia products from KND have an appropriate hardness with less chipping during the milling process thanks to the raw materials manufactured and refined in-house. Also, after the sintering procedure, it offers excellent chipping resistance, especially during very challenging marginal adjustments.

Is there anything else that sets KATANA™ Zirconia YML apart from other products with an integrated strength gradient?

Yes, KATANA™ Zirconia YML offers reduced sintering deformation, thanks to in-house developed raw materials, based on proprietary technology to control shrinkage rate. Moreover, we offer a wide range of shades (14), which is another important aspect (apart from the material’s well-balanced aesthetic properties and absence of transition lines) for the creation of lifelike restorations. Finally, since three out of four layers meet the conditions for an ISO class 5 classification, there are few restrictions on the design variation of the prosthesis.

Why should a dental technician consider using KATANA™ Zirconia YML instead of any other dental zirconia (in your opinion)?

Atsushi Matsumoto:

It is now possible for dental technicians to produce strong and aesthetic restorations with just one material, KATANA™ Zirconia YML. This allows for a reduced inventory, while working time is significantly shortened due to the possibility of high-speed sintering.

Yuta Tajima:

To my mind, the most convincing properties are excellent firing accuracy due to well-balanced material properties across all layers, the wide range of shades available and the great design flexibility even when designing long-span bridges. Last but not least, the trusted quality of the KATANA™ brand and the label “Made in Japan” are reasons to opt for this new product.

All blanks from the KATANA™ Zirconia Series stand out from other dental zirconia materials due to their particularly fine-grained, densely pressed microstructure, which is the basis for a superior surface quality, edge stability and the resulting accuracy of fit. What is the secret behind this exceptionally high blank quality?

Since we do not know the correlation between marginal stability properties (chipping, etc.) and material compositions, structures etc., it is very difficult to answer this question. It may depend on the structures of the zirconia crystals, the raw material itself, the correct strength level after pre-sintering or any other minor factor during the manufacturing process of the disc. All these factors together, of course, are important.

We are using pigments developed by KND, which have an excellent colour stability without fading even after the final sintering procedure.

Even if the restoration margins have been milled to a very thin profile, they still show smooth margins without any chipping.

A clear advantage of the KATANA™ Zirconia series, much praised by KND's Key Opinion Leaders, is its colour stability and shade match to the "VITA classical shade guide". Can you explain the importance of an in-house conducted addition of additives and color pigments in form of metal oxides to satisfy the user and distinguish KATANA™ Zirconia from competitors’ products?

We are using pigments developed by KND, which have an excellent colour stability without fading even after the final sintering procedure. The particle size is appropriately controlled. In addition, our professional "colour mixing" staff, reflecting the opinions of clinically experienced dental technicians both inside and outside the company, have achieved a pigment mixture that shows only a slight change in shade even in cases with different thicknesses.

What is your vision with regard to future developments in dental zirconia?

Since the introduction of zirconia on the dental market, many significant material advances have been achieved. Today, there are high-strength, low light-transmitting zirconia materials up to high light- transmitting, low strength zirconia materials available on the market. Furthermore, there are now also high light-transmitting, low strength zirconia materials in mixed systems (YML series) offered. Our foremost goal is to develop the ultimate zirconia in near future, combining both high strength and high light transmission, which breaks the general expectation of a compromise between strength and translucency within zirconia materials.

|

|

| Atsushi Matsumoto |

Yuta Tajima |