Clinical advantages of “KATANA™ Zirconia” YML as related to an external organization’s test results

By PhD. M. Inokoshi.

INTRODUCTION

Kuraray Noritake Dental Inc. is a manufacturer with a long history and wealth of experience in the field of producing dental materials, including bonds, cements and ceramics. The all-ceramic restorations market, including that for zirconia products, has been growing rapidly around the world since the beginning of the 2000’s. In response to this trend, we have established an integrated production system that can be used to manufacture a wide range of dental zirconia products in-house, from powder to discs.

When we develop new zirconia products, we carefully analyze the characteristics of dental zirconia that are actually demanded by users in the clinical setting and, based on the results of our analysis, we craft new products with these clinically needed characteristics. In our first efforts we focused on developing a dental zirconia that would have a natural tooth color after sintering. We launched “KATANA™ Zirconia”, our first dental zirconia product to span all the VITA* Classical A1-D4 shade Guide, in 2007. Following in 2013, using our original manufacturing method, we developed and launched “KATANA™ Zirconia” ML (Multi-Layered), a multi-layered zirconia product that produces smooth color gradations like those of natural teeth, avoiding sharp color transition between layers. Then, in 2015, we also released “KATANA™ Zirconia” UTML (Ultra Translucent Multi-Layered) and STML (Super Translucent Multi- Layered). These are highly translucent, multi-layered zirconia products that became other versions of our multi-layered zirconia family. We are one of the pioneering manufacturers of dental zirconia, and as such, we promise ourselves that we will keep on delivering excellent highly-esthetic dental zirconia products to the dental market now and into the future.

*VITA is a trademark of VITA Zahnfabrik, Bad Sackingen, Germany.

Recent advancements in dental technology have made it possible to use zirconia as a prosthetic material across a wide variety of dental applications, from large-sized implants where great mechanical strength is required, to treatment in the anterior region, where esthetics are of the utmost importance. The material characteristics needed, however, differ from one treated case to another. Many dental zirconia suppliers respond to these therapeutic requirements by offering various types of dental zirconia that feature different levels of mechanical and esthetic properties. This requires dentists and dental technologists in clinical settings to select, from a wide range, the type of zirconia that will be more better appropriate to treat the case they are facing at any given moment. This means it is necessary for each clinic to keep in stock many types of dental zirconia materials with different characteristics, in order to meet the requirements of the wide variety of possible case parameters.

Several dental material manufacturers have responded to these circumstances by offering dental zirconia disc products that have combinations of multiple layers with different levels of translucency and mechanical strength. They claim these products make materials available that can be used to fabricate a wide range of restorations. These products, however, can have serious shortcomings. Some require laborious manufacturing work, tailored to the fabrication of the particular restoration. Others do not include the required high-strength zirconia layer that makes it possible to fabricate a bridge. These products, therefore, may provide no assurance of providing the mechanical strength recommended by ISO for the manufacture of certain restorations. A market need arose for dental zirconia products that could be used easily and safely for the fabrication of a wide range of restorations.

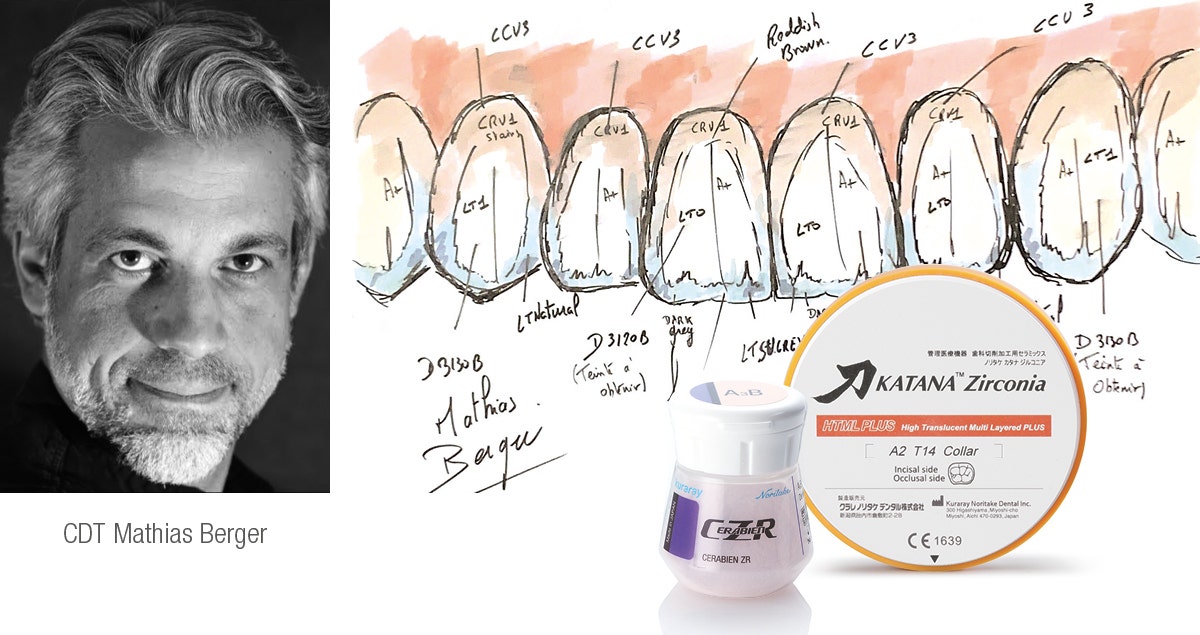

In response to this need, at Kuraray Noritake Dental Inc., we have developed and released “KATANA™ Zirconia” YML(YML), a new type of dental zirconia material that provides the blend of excellent performance variables provided by the “KATANA™ Zirconia” Multi-Layered series. With its well-balanced performance, the YML can be indicated for the fabrication of a wide range of restorations, from large sized ones requiring great mechanical strength to anterior crowns that require a high level of translucency In this paper, we would like to describe YML’s features and the technology behind it. We will also present comparative data collected by Masanao Inokoshi, a professor in the Department of Gerodontology and Oral Rehabilitation at Tokyo Medical and Dental University, Graduate School of Medical and Dental Sciences, on YML and a similar product from the competition.

FEATURES OF THIS PRODUCT AND THE TECHNOLOGY BEHIND IT

Short sintering time

YML can be baked satisfactorily in a short period of time, thanks to our innovative technology. In addition to the conventional sintering schedule of about 7 hours, and even the 90-minute schedule, we have also made it possible to shorten the sintering time further, to a remarkable 54 minutes*.

*The material is removed from the furnace at 800°C / 1472°F. Up to 3-unit bridges.

Excellent translucency and great mechanical strength

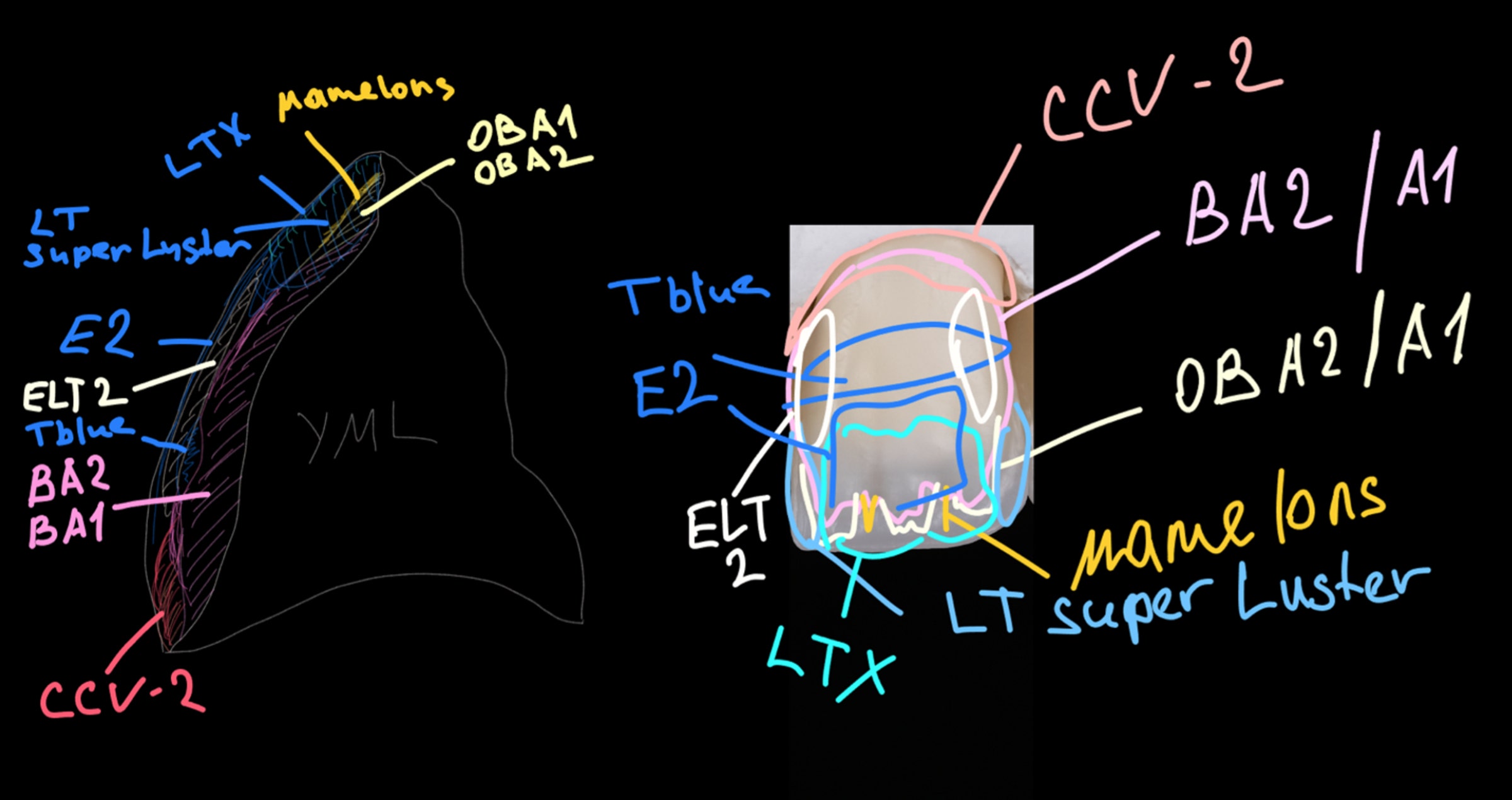

A YML disc consists of four layers: one Enamel and three Body layers. The top Enamel layer (35% of the total thickness: 750 MPa*1) is composed of the same zirconia material as “KATANA™ Zirconia” STML, which is highly acclaimed for its excellent translucency. The three Body layers ((1): 1,000 MPa*1, (2): 1,100 MPa*1 and (3): 1,100 MPa*1) that lie below the Enamel layer are made from a new type of zirconia material. Body layer (1) is an intermediate layer that has the desirable translucence of STML. It includes, however, a well-balanced combination of translucency and mechanical strength suitable for the treatment of cases, such as those requiring bridges, which demand these notable characteristics. Body layers (2) and (3) provide the high level of mechanical strength of “KATANA™ Zirconia” HTML suitable for the fabrication of large-sized restorations, along with an improved level of translucency. With its well-balanced combination of translucency and mechanical properties, provided by taking advantage of multiple zirconia ceramics, YML is a product that meets the demand for highly esthetic products. It is suitable for the fabrication of the whole range of restorations, from single crowns to bridges.

*1 : According to ISO 6872: 2015, three-point bending test.

Multi-layer gradation

Kuraray Noritake Dental Inc. released our first multi-layered zirconia product in 2013. Subsequently, the company launched zirconia products very much appreciated for their smooth transition of color gradation, much like that of natural teeth. We use our own innovative pressing method to manufacture YML. It smooths the change of colors between layers, which provides the desirable feature of a very smooth and natural color transition.

Reduced deformation after sintering

In general, dental zirconia shrinks during the sintering process by about 20 percent in 2 dimensions (50 percent in volume). If shrinkage cannot be controlled adequately, it becomes difficult to fabricate restorations that fit precisely into complicated abutments or margin lines. The shrinkage of zirconia materials varies subtly from one production lot to another, even when the same raw material is used. We appropriate raw material control such as raw material crushing etc., using different sintering shrinkage rates for different production lots. In view of the fact that the sintering shrinkage of zirconia materials requires delicate control, it is not hard to understand that shrinkage control is even more difficult when different zirconia materials are combined into one disc. If the shrinkage rates of the layers of a zirconia disc differ, the restoration will necessarily be deformed during shrinkage. Many users voiced particular concerns about dimensional stability when they were asked about using zirconia discs (which require high precision) for the fabrication of implants. Kuraray Noritake Dental Inc. has an integrated production system that is used to manufacture zirconia products in-house, from the design and manufacture of zirconia powder as a raw material to final products, thus making it possible for us to control the shrinkage rate of zirconia with great accuracy. For this reason, we are able to use zirconia materials with stably controlled shrinkage rates to manufacture YML, even though it consists of multilayers made up of different zirconia materials. This minimizes deformation of restorations after shrinkage.

RESULTS OF A VERIFICATION OF THE PHYSICAL PROPERTIES OF YML AND A REVIEW OF ITS CLINICAL ADVANTAGES

To verify the physical properties of YML, the translucence, mechanical strength and crystalline structure of YML and ZirCAD Prime (Ivoclar Vivadent) were analyzed and compared with one another at the Tokyo Medical and Dental University. Among the physical properties examined, this paper focuses especially on data on the translucency and mechanical strength of each product.

Data on translucency:

Different alphabets indicate a definite difference between groups.

Data Courtesy of PhD. Masanao Inokoshi, Tokyo Medical and Dental University.

The translucency of ZirCAD Prime was significantly higher than that of YML, when a comparison was made at the Enamel layer. This is probably because Prime contains almost no pigment in the Enamel layer, in order to bring out the brightness (whiteness) of the zirconia itself. By contrast, YML contains some pigment, so the product can deliver an optimal level of brightness in the clinical setting. That is, it seems that the addition of pigments leads to a difference in translucency between YML and Prime.

Data collected at Kuraray Noritake Dental on the relative translucency of YML and Prime

Total light transmittance (%) (Illuminant: D65; test specimens with a diameter of 30 mm, and a thickness of 1 mm) Raw material in YML’s Enamel layer (no coloring agent): 49% Prime’s Enamel layer: 49%.

Regarding the layers lying beneath the Enamel, such as the Transition and Body layers, YML was found to be more translucent than Prime. It can be concluded that YML is sufficiently translucent even beneath the layers lying beyond the Enamel layer. This makes it possible to fabricate prostheses with natural tooth colors, when used in combination with an Enamel layer that is suitably adjusted to provide the optimum color.

Mechanical strength data as results of four-point bending test:

Different alphabets indicate a definite difference between groups.

Data Courtesy of PhD. Masanao Inokoshi, Tokyo Medical and Dental University.

The Enamel layer of YML had a significantly greater bending strength than that of Prime. On the other hand, when the bending strength of the Body layers was compared, Prime’s Body layer was the strongest. The three YML Body layers ((1), (2) and (3)) had bending strength values of more than 850 MPa*2, and there were no significant differences in bending strength among Prime’s Body layer and YML’s Body layers ((1), (2) and (3)).

The results revealed that while YML has small differences in bending strength among the Enamel layer and the three Body layers, Prime has clearly different levels of bending strength between the Body layer and the other two layers. YML’s Body layers (including the intermediate layer) have such a high level of mechanical strength that it is quite feasible to use it to fabricate highly reliable prostheses.

*2 : According to ISO 6872: 2015, four-point bending test.

LAYERED DESIGN CONCEPT

The guide for fabricating large restorations using YML states the requirement that at least 50% of the connector cross-section should be positioned in the bottom (lower part) of the disc. This means that generally you can meet the requirement of the guide by positioning the restoration at the center of the disc’s four layers. Guides or advices of restoration fabrication for using zirconia discs available in the market may sometimes be complicated to position the restoration as specified in the guide or to position the piece as specified by the guide, which makes it difficult to fabricate a highly esthetic restoration that makes use of the Enamel layer’s better translucency.

When we developed YML, Kuraray Noritake Dental kept in mind that the fabrication guide must be practical, as well as easy. That’s why YML was designed with a sufficiently thick Enamel layer that permits a high level of esthetics for any type of restoration that might be fabricated.

CONCLUSION

“KATANA™ Zirconia” YML is our new zirconia disc product, which features a well-balanced combination of mechanical strength and esthetics. It has been developed by using our innovative zirconia manufacturing technology, as well as bringing together the essence of the development and production technology of multi-layered zirconia discs. We hope YML will be one of the options of choice for zirconia materials available to dentists and dental technologists who need to use multiple zirconia materials for various applications or who have concerns about the mechanical strength and esthetic properties of the zirconia materials they are currently using.

YML LINEUP